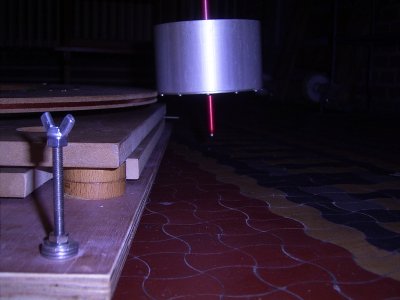

This is about the one-time experiment in the Chapel at Vrijland.

In brief:

Sunday sept 23 the cable in the chapel was broken after just over 24 hours of service

This is extremely fast for a piano wire of 0.92 mm and a bob weight of 14 kg

Suspicion is a notching effect by a sharp edge of the clamp.

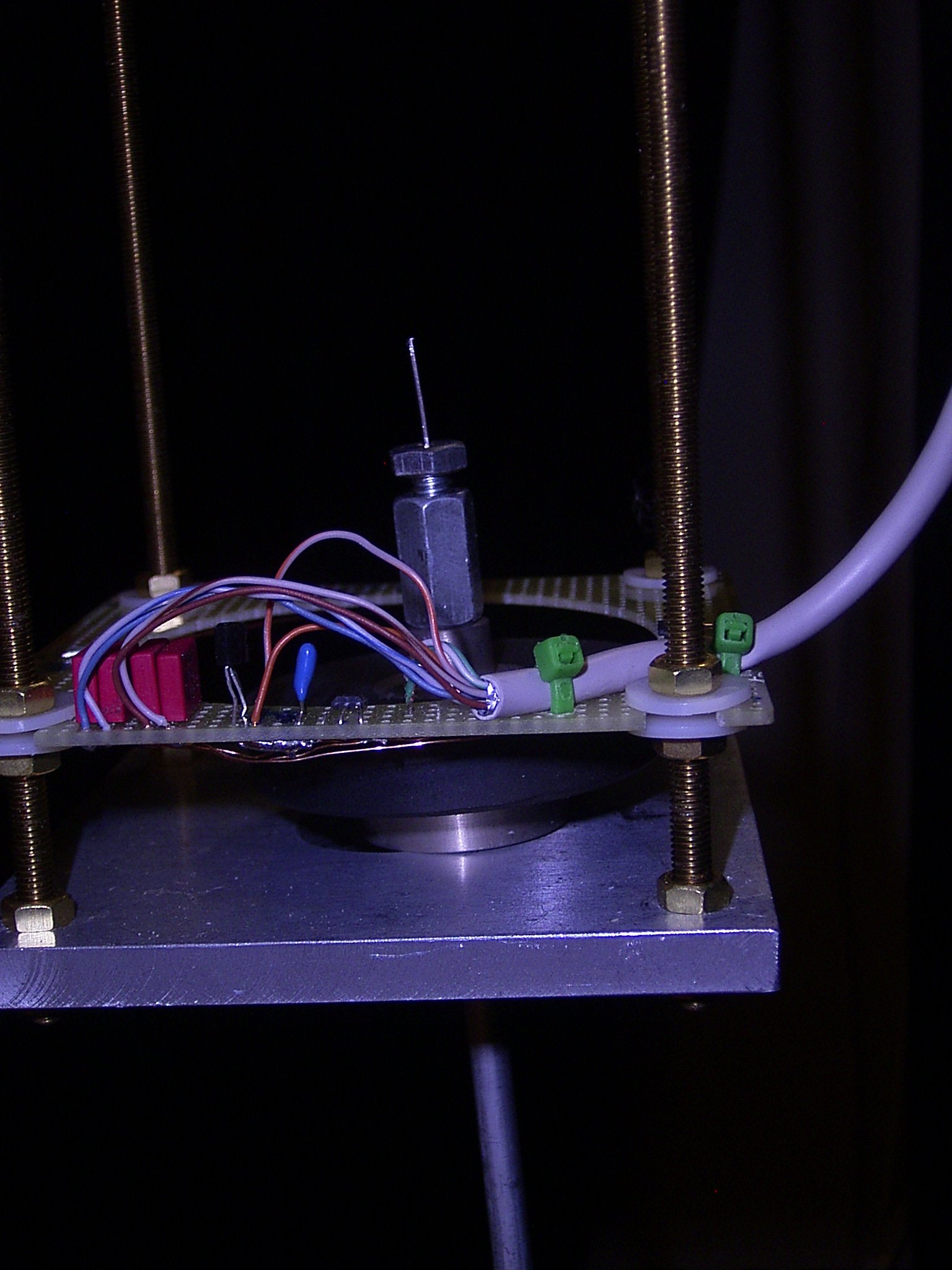

Inspection sunday 09_24: The Bob was hanging to the side of the RimCoil.

It came down ca. 10 cm. The full weight was still on the cable.

The lower plate of the TopMount catched the magnet carrier.

The 6mm alu-tube was pulled down through the magnet carrier.

The wire was pulled through the tube for a few centimeters.

Most likely, when the cable breaks, it it will do that at the moment of center passing, because then the force on the cable is maximal.

The TopMount with the upper part of the cable was taken home for investigation.

The cable in the chapel was in 2 parts, from top ca. 1.30 m, the rest was one piece. The pieces were coupled by small loops.

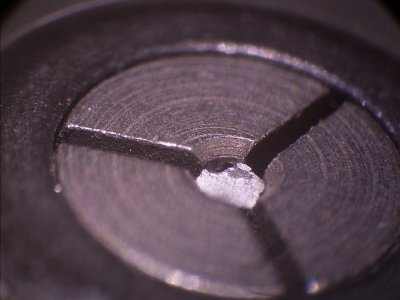

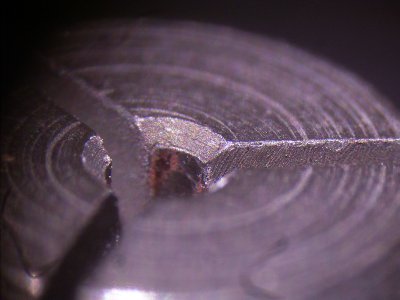

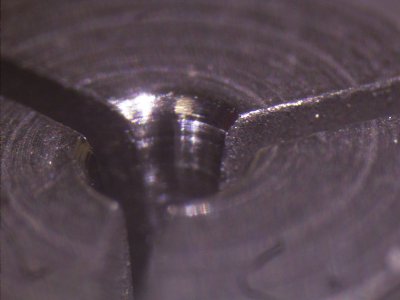

The fracture in the Proxxon clamp under the microscope. Clearly visible is that the wire broke at the edge of the clamping.

The piano wire showed now to be hexagonal. I did not notice that before. I guess this is not beneficial for a reliable clamping, the clamp is designed for round objects (PCB-drills).

The edge of the clamp looks quite sharp.

I milled the edge a little bit conical / trumpet shaped and polished it with the tools below.

I used these Dremel tools, a tapered cutter and a polishing tip made from somewhat soft material.

Do not use a tapered diamond tip. At this scale the diamonds are rather rough and cut grooves which are hard to polish.

Monday sept 25 in the afternoon the pendulum was re-installed and started again.

I changed the way of clamping a little bit, the wire was bent quite sharply just above the clamping insert so it does not easily slip out, and the clamp itself was tighted with moderate force to prevent the notching effect. Earlier the clamping was done with strong force to prevent it to slip out.

Thursday sept 28 the cable broke again at 16:52. Inspection showed that the fracture was deeper inside the clamp.

From here on I abandoned the hexagonal cable. Instead I used a 50cm long piece of 1.3 mm diam spring steel which had never been rolled up and so was quite straight. To prevent slipping out I used the metal part from a lustre terminal with the two screws. For the long part I used a 1mm diam twined steel cable, 7 strings of 7 thin wires. The cables were coupled by short loops.

Again a problem ocurred: During installation the cable already slipped out of the lustre terminal. The next step was to bend the top of the cable in the shape of a question mark, such that it would rest on the clamp.

With this setup I could show the pendulum working during the Hack42 Open Day at october 8, the "Weekend of Science" when many science institutions open their doors for the public.